Have you heard the news?! Acumatica 2024 R1 is officially available as of Wednesday, March 20th. The first of Acumatica's 2024 biannual product updates release includes updates to their Retail, Distribution, Construction, and Manufacturing Editions, as well as the cloud ERP's Core features and Developer updates.

5 min read

Acumatica 2024 R1 Release!

By Ashley Spence on Fri, Apr 05, 2024 @ 09:32 AM

Topics: eCommerce Manufacturing Distribution Acumatica Cloud ERP Business Management Software

5 min read

Acumatica 2019 R1: Product Enhancements, Improved Usability, and More!

By Ashley Lemus on Wed, Apr 03, 2019 @ 04:34 PM

The newest version of Acumatica is here -- providing more product enhancements and improved usability than ever before!

As mentioned in our Acumatica Summit 2019 Recap, Acumatica announced their latest release - 2019 R1 - which provides comprehensive product enhancements allowing users to experience improvements to the product, specifically the financial management, inventory management, project accounting, and field service management modules.

Topics: Manufacturing Acumatica Cloud ERP

3 min read

Acumatica Wins SIIA CODiE Award for Best Cloud ERP & Best Manufacturing Solution

By Ashley Lemus on Thu, Feb 21, 2019 @ 04:41 PM

We're excited to announce Acumatica's 2nd year in a row being honors at the SIIA Annual Conference and CODiE Awards.

This year they're bringing home Best Cloud ERP Solution 2018

and Best Manufacturing Solution 2018!

Topics: Manufacturing

2 min read

Speed-Up Manufacturing Orders w/ Acumatica Cloud ERP!

By Ashley Lemus on Thu, Oct 26, 2017 @ 12:25 PM

Webinar Alert!

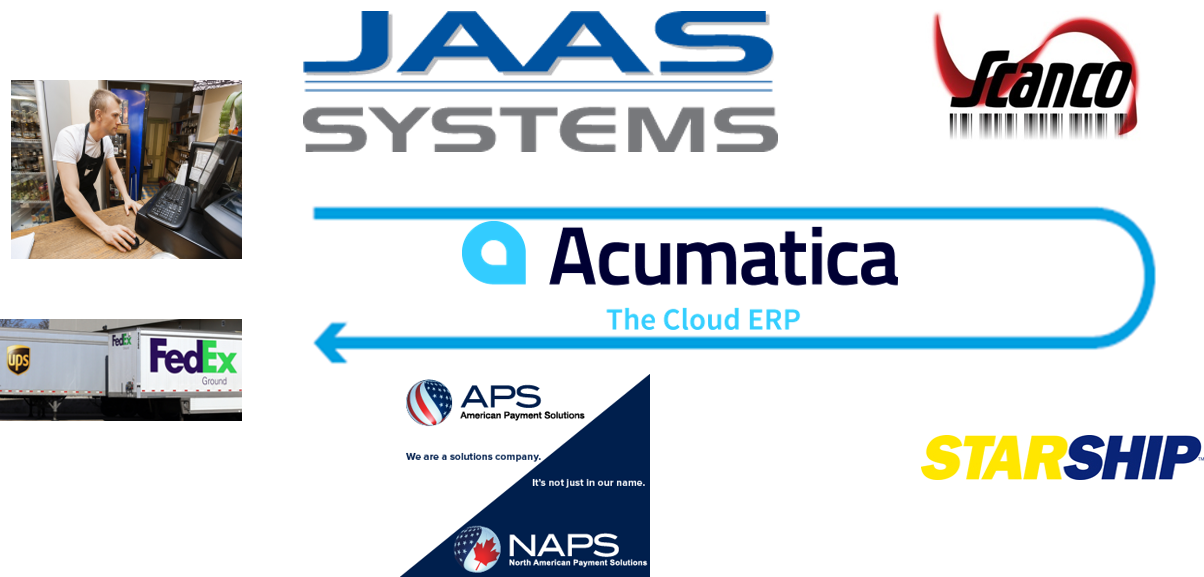

Acumatica Cloud ERP has joined forces with Artsyl, Scanco, StarShip, and American Payment Solutions to provide this complimentary webinar!

Topics: Manufacturing Acumatica Cloud ERP Webinar Solution Enhancements

2 min read

How Food Companies Can Mitigate the Risks of a Global Supply Chain

By Ashley Lemus on Mon, May 08, 2017 @ 01:43 PM

Did you know that more than 75% of food manufactures attribute the fastest-growing risk for business continuity to increased supply chain complexity?

Topics: Manufacturing Business Management Software Supply Chain Management

2 min read

Webinar Alert: Automate Manufacturing & Order Fulfillment Processes

By Ashley Lemus on Mon, Apr 17, 2017 @ 03:20 PM

Join our friends at Acumatica, JAAS Systems, Scanco, American Payment Solutions, and StarShip to learn how an integrated streamlined manufacturing and order processing solution for Acumatica Cloud ERP saves customers time and money!